How a 3D Printed Parts Manufacturer Can Speed Up Your Prototyping

- hktenlita1

- Apr 16

- 4 min read

In today’s fast-paced product development cycle, speed and agility are more important than ever. Whether you’re a startup with a novel idea or an established manufacturer looking to improve an existing product, prototyping plays a pivotal role. Traditional manufacturing methods, while reliable, often come with long lead times, high costs, and limited flexibility. This is where 3D printing, or additive manufacturing, has stepped in to revolutionize the prototyping landscape.

The Role of a 3D Printed Parts Manufacturer in Product Development

A 3D printed parts manufacturer is not just a supplier; they are a strategic partner in product innovation. These manufacturers bring to the table advanced printing technologies, material expertise, and design know-how that can drastically shorten the product development timeline. Their role extends beyond printing—they offer guidance on design for manufacturability, materials selection, and iterative testing.

Speed and Flexibility in Design Iteration

One of the most significant advantages of working with a 3D printed parts manufacturer is the speed at which design iterations can be completed. In traditional manufacturing, modifying a prototype could take weeks, especially if it involves retooling or mold adjustments. With 3D printing, changes can be made digitally and implemented almost immediately. This capability allows engineers and designers to test multiple design variations in a fraction of the time.

Eliminating the Need for Tooling

Tooling is often one of the most time-consuming and costly aspects of traditional prototyping. It involves creating custom molds or dies to produce a part, which can take weeks or even months. A 3D printed parts manufacturer bypasses this step entirely by building parts layer by layer directly from a digital model. This not only saves time but also reduces the upfront cost significantly.

Material Versatility for Diverse Prototypes

3D printed parts manufacturers offer a wide array of materials suitable for different prototyping needs. Whether it’s a functional prototype that needs to withstand mechanical stress or a cosmetic model for investor presentations, the right material can be selected to meet the exact requirements. This versatility ensures that each iteration is not only fast but also fit for purpose.

Reducing Waste and Optimizing Resources

Traditional subtractive manufacturing methods often result in significant material waste, especially when machining parts from solid blocks of material. 3D printing is an additive process, which means material is used only where needed. This not only reduces waste but also optimizes resource usage, making the entire prototyping process more sustainable and cost-effective.

Real-Time Prototyping and On-Demand Production

Partnering with a 3D printed parts manufacturer allows for real-time prototyping. Components can be produced on-demand without waiting for batch production runs. This capability is especially useful in agile development environments, where rapid iteration and testing are critical to success. It enables teams to respond to testing feedback or market demands almost instantly.

Enhancing Communication and Collaboration Across Teams

Having a physical prototype in hand early in the design process can significantly improve communication among cross-functional teams. Engineers, designers, marketers, and stakeholders can all interact with the prototype, providing more accurate feedback. A 3D printed parts manufacturer ensures that prototypes are delivered quickly and accurately, fostering a more collaborative and informed development process.

Lowering the Barrier for Innovation

For startups and small businesses, the high cost and complexity of traditional prototyping can be a major barrier to innovation. A 3D printed parts manufacturer democratizes access to advanced manufacturing by offering low-cost, scalable prototyping solutions. This lowers the risk associated with new product development and encourages more experimentation and creativity.

Case Studies of Accelerated Prototyping

Numerous companies have successfully leveraged the expertise of 3D printed parts manufacturers to accelerate their product development. From consumer electronics to automotive components, the ability to quickly prototype, test, and iterate has resulted in faster time-to-market and improved product quality. These case studies underscore the tangible benefits of adopting additive manufacturing in the early stages of design.

Bridging the Gap to Full-Scale Production

While 3D printing is primarily used for prototyping, its role is expanding into low-volume and even full-scale production. A 3D printed parts manufacturer can help bridge the gap between prototype and production by offering hybrid solutions that combine additive and traditional manufacturing methods. This approach enables a smoother transition and ensures that the final product maintains the integrity of the prototype.

Access to Advanced Technologies and Expertise

Working with a dedicated 3D printed parts manufacturer gives you access to cutting-edge technologies like SLA, SLS, FDM, and more. Each of these technologies has its strengths and is suited to different types of prototypes. The manufacturer’s expertise in these areas ensures that your prototype is built using the most appropriate method, thereby optimizing both performance and cost.

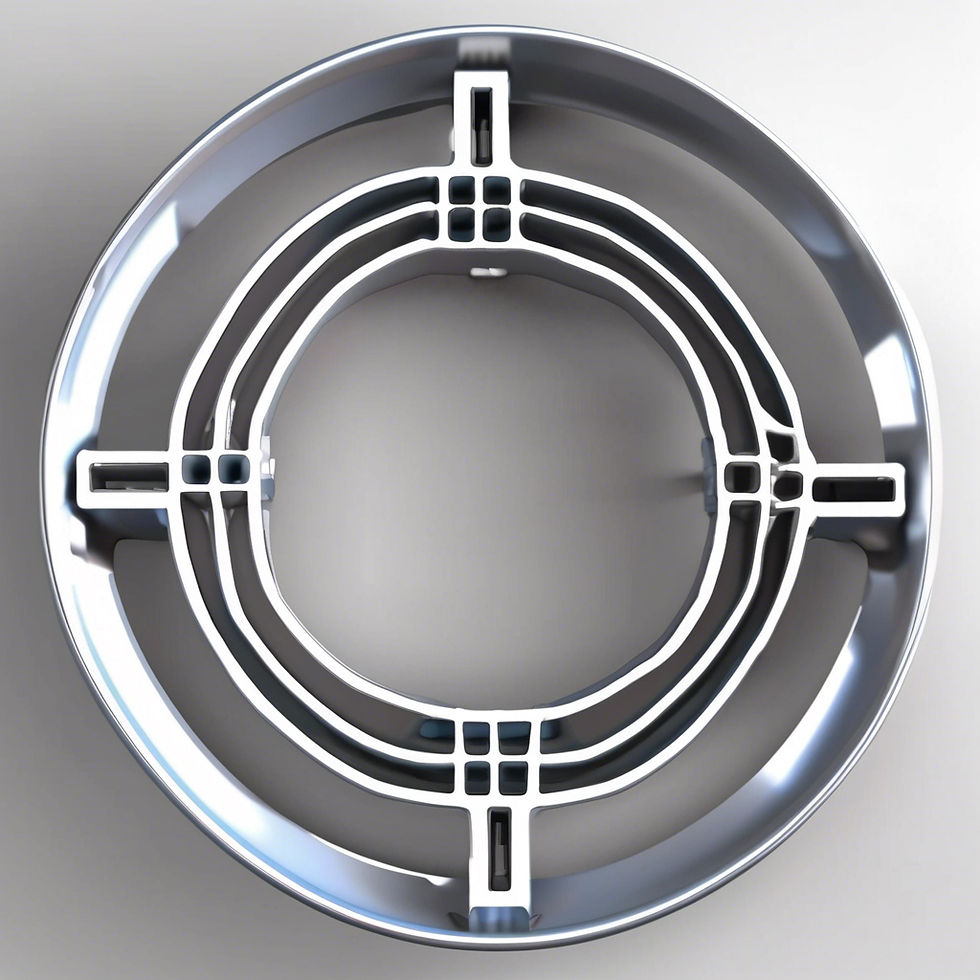

Customization and Complex Geometry Made Simple

Complex designs that would be difficult or impossible to produce using traditional methods can be easily realized through 3D printing. A 3D printed parts manufacturer can produce intricate geometries, internal structures, and customized components without added complexity or cost. This opens up new possibilities for innovation and design optimization.

Improving Product Testing and Validation

Prototyping is not just about appearance; it’s about testing functionality, ergonomics, and performance. A 3D printed parts manufacturer ensures that your prototypes are accurate and durable enough for real-world testing. This leads to better validation and fewer surprises during the final production phase, ultimately resulting in a more robust and market-ready product.

Supporting Rapid Market Entry and Competitive Advantage

In competitive industries, the ability to bring a product to market quickly can be a key differentiator. By speeding up the prototyping process, a 3D printed parts manufacturer enables faster market entry. This can be particularly advantageous for capturing early market share, responding to customer feedback, or launching seasonal or limited-edition products.

Conclusion

Choosing a 3D printed parts manufacturer for your prototyping needs is more than a tactical decision—it’s a strategic move that can shape the success of your product development. From faster iterations and reduced costs to enhanced testing and better team collaboration, the benefits are clear. As additive manufacturing continues to evolve, its role in rapid prototyping will only become more vital, empowering innovators to turn their ideas into reality with unprecedented speed and precision.

Comments