How CNC Machining Parts Exporters Ensure Precision and Quality

- hktenlita1

- Apr 16

- 4 min read

Computer Numerical Control (CNC) machining has revolutionized the manufacturing landscape by offering unmatched precision, repeatability, and efficiency. From aerospace to automotive, electronics to medical devices, CNC machining has become the backbone of modern industrial production. As global demand grows, CNC machining parts exporters play a pivotal role in delivering high-quality components to international markets. Their responsibility extends beyond production to include stringent quality control and adherence to international standards.

Understanding the Role of CNC Machining Parts Exporters

CNC machining parts exporters serve as the vital link between manufacturers and global buyers. Their primary function is to ensure that parts produced in one country meet the specifications, standards, and expectations of clients worldwide. These exporters often work closely with production facilities, managing supply chains, overseeing quality control processes, and handling international logistics. Their ability to meet tight deadlines while ensuring quality has made them invaluable in global trade.

Commitment to International Standards and Certifications

To be competitive on a global scale, CNC machining parts exporters must comply with internationally recognized standards and certifications. These may include ISO 9001 for quality management, ISO 13485 for medical devices, and AS9100 for aerospace components. Adhering to these standards is not only a mark of credibility but also a testament to their commitment to producing high-quality, defect-free parts. Exporters typically undergo rigorous audits and inspections to retain these certifications, ensuring continuous improvement.

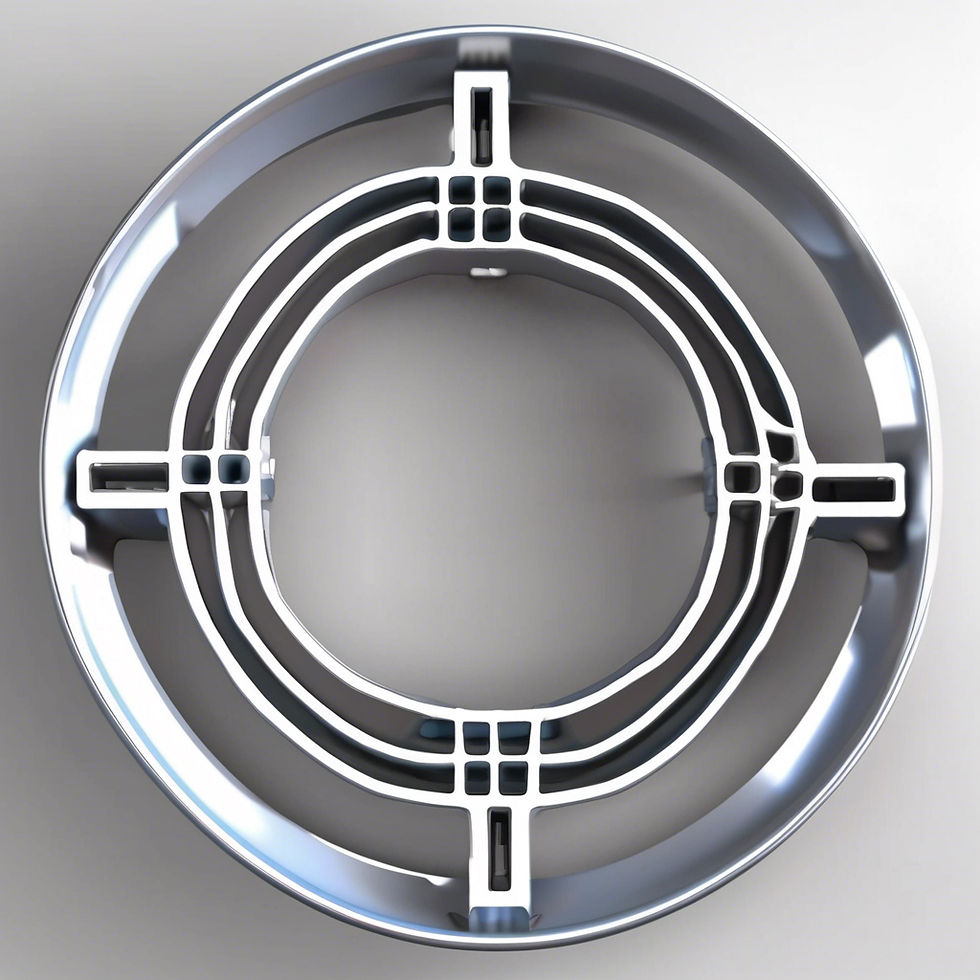

Advanced CNC Machinery and Cutting-Edge Technology

One of the most significant ways exporters ensure precision and quality is by investing in advanced CNC machinery. Multi-axis machines, high-speed mills, and robotic automation systems allow for complex geometries and tighter tolerances. State-of-the-art software programs for computer-aided design (CAD) and computer-aided manufacturing (CAM) enhance the accuracy of designs and minimize human error. Real-time monitoring systems and data analytics also help in optimizing machine performance and detecting deviations early in the production process.

Skilled Workforce and Continuous Training Programs

Behind every precision-machined component is a skilled technician or engineer. Exporters understand the importance of human expertise in operating sophisticated machinery and interpreting technical drawings. Many CNC machining parts exporters invest in regular training programs to keep their workforce updated with the latest machining techniques, material science innovations, and quality assurance protocols. This ongoing education ensures consistency in output and fosters a culture of excellence.

Quality Control Mechanisms and Inspection Procedures

Quality control is at the core of any CNC machining operation. Exporters implement comprehensive inspection processes throughout the production cycle. This includes first-article inspections, in-process monitoring, and final product verification. Advanced tools such as coordinate measuring machines (CMM), optical comparators, and laser scanners are used to ensure that each part meets dimensional and surface finish specifications. Statistical process control (SPC) methods help in identifying trends and reducing variability.

Material Selection and Supplier Evaluation

The quality of CNC machined parts heavily depends on the materials used. Exporters maintain a strict protocol for material selection, sourcing only from verified and certified suppliers. Material properties such as hardness, tensile strength, corrosion resistance, and machinability are carefully considered to match the application requirements. In addition, exporters perform incoming material inspections and maintain traceability records to ensure compliance with client specifications and industry standards.

Customization and Client Collaboration for Tailored Solutions

Global buyers often require parts that are unique to their applications. CNC machining parts exporters excel in offering customized solutions by closely collaborating with clients. Through detailed consultations and prototype testing, exporters gain insights into client needs and translate them into precise components. The ability to produce low to medium volume runs without compromising quality is particularly attractive to industries with specialized requirements.

Packaging, Documentation, and Compliance for Global Shipping

Precision doesn’t end with production; it extends to packaging and logistics. CNC machining parts exporters pay meticulous attention to packaging materials and methods to prevent damage during transit. Anti-corrosion treatments, vacuum sealing, and shock-resistant containers are commonly used. Moreover, detailed documentation including material certificates, inspection reports, and customs declarations is prepared to ensure smooth clearance and compliance with international regulations.

Leveraging Digital Platforms for Transparency and Tracking

With globalization, transparency has become crucial in international trade. Exporters leverage digital platforms for real-time tracking, order management, and client communication. These systems offer buyers visibility into the production and shipping stages, enabling them to plan better and avoid delays. Blockchain and IoT technologies are also being adopted to enhance traceability and data security across the supply chain.

Building Long-Term Partnerships Through Reliability and Support

Success in the CNC machining export business is built on trust and reliability. Exporters aim to establish long-term relationships by offering consistent quality, prompt support, and competitive pricing. Post-sale services such as warranty, technical assistance, and feedback integration play a vital role in client retention. By positioning themselves as strategic partners rather than just suppliers, CNC machining parts exporters foster loyalty and mutual growth.

Sustainability Practices and Environmental Responsibility

In response to growing environmental concerns, many exporters are adopting sustainable practices. This includes waste reduction through recycling, energy-efficient machining processes, and environmentally friendly packaging. Compliance with environmental regulations such as RoHS and REACH demonstrates a commitment to responsible manufacturing. Buyers increasingly favor suppliers who prioritize sustainability as part of their corporate social responsibility.

Challenges Faced and How Exporters Overcome Them

Exporting CNC machined parts comes with its share of challenges, including fluctuating raw material prices, geopolitical tensions, and evolving trade regulations. However, experienced exporters mitigate these risks through strategic sourcing, diversification of markets, and agile supply chain management. Continuous investment in technology and human capital also equips them to adapt quickly to changes and maintain their competitive edge.

Future Trends and Innovations in CNC Machining Exports

The future of CNC machining exports is shaped by rapid technological advancements. Integration of artificial intelligence (AI) and machine learning is improving predictive maintenance and process optimization. Additive manufacturing (3D printing) is being used in conjunction with CNC machining for hybrid production models. Exporters who embrace these innovations are better positioned to meet the evolving demands of global buyers.

Conclusion

CNC machining parts exporters play a crucial role in the global manufacturing ecosystem by ensuring that every part delivered meets the highest standards of precision and quality. Through technological investments, skilled workforce, stringent quality control, and client-focused services, these exporters uphold their reputation in the international market. As industries continue to demand excellence, the commitment of CNC machining parts exporters to precision and quality remains the foundation of global trust and collaboration.

Comments