Why Global Industries Rely on CNC Machining Parts Exporters

- hktenlita1

- Apr 16

- 5 min read

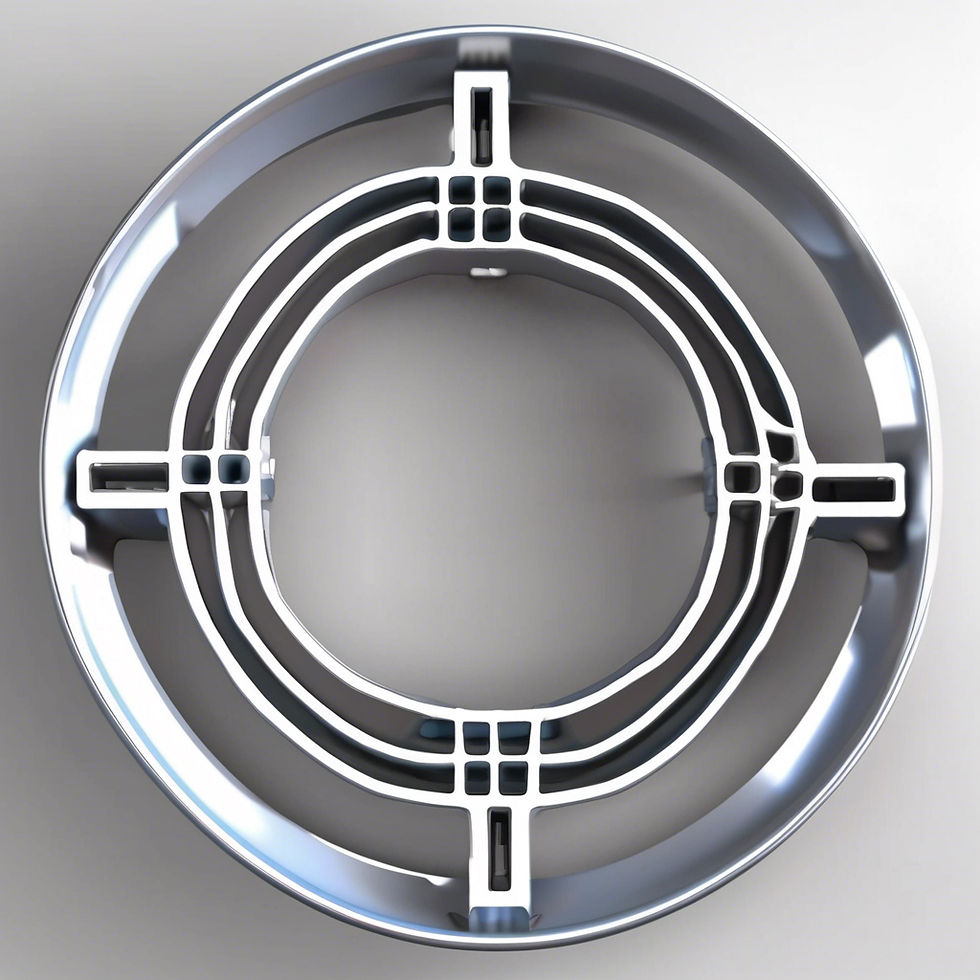

CNC (Computer Numerical Control) machining has transformed how parts are manufactured, enabling high-precision, repeatable production with excellent efficiency. From small intricate components to large-scale industrial machinery parts, CNC machining serves as a cornerstone of production across countless sectors. At the center of this global revolution are CNC machining parts exporters who bridge the gap between high-quality manufacturing and international demand. Their importance is underscored by the increasing reliance of global industries on their expertise, capabilities, and dependable supply chains.

The Expanding Role of CNC Machining Parts Exporters

Globalization has expanded the reach of CNC machining beyond local factories to international markets. CNC machining parts exporters have stepped into a crucial role—offering consistent, high-precision components that meet global standards while navigating international logistics and compliance requirements. These exporters are not just manufacturers; they are partners in innovation, supply chain facilitators, and quality custodians, helping industries worldwide stay competitive and efficient.

Meeting the Demands of Diverse Global Industries

Industries such as aerospace, automotive, medical devices, electronics, energy, and robotics all have stringent demands for precision and quality. CNC machining parts exporters cater to each of these by understanding their unique requirements. Whether it's aerospace-grade aluminum brackets, titanium orthopedic implants, or intricate automotive gears, exporters ensure these components are manufactured to exact specifications. Their adaptability across industries makes them indispensable partners in global production chains.

Ensuring International Compliance and Standards

Exporters of CNC machined parts operate under rigorous international standards such as ISO 9001, AS9100, and ISO 13485. Compliance with these certifications ensures that their processes are reliable, controlled, and consistently produce parts that meet safety and quality benchmarks. For global buyers, working with certified exporters eliminates risk and simplifies vendor approval processes. These standards also demand continuous improvement, pushing exporters to evolve in sync with global expectations.

Technological Advancements Driving Precision and Efficiency

To meet the high demands of global clients, CNC machining parts exporters invest in cutting-edge machinery and software. Five-axis machining centers, real-time monitoring systems, and high-speed milling tools enhance both speed and accuracy. In addition, the integration of CAD/CAM software allows seamless transition from design to production, reducing errors and cycle times. As a result, exporters can handle complex geometries, tight tolerances, and rapid prototyping efficiently—delivering both speed and precision that industries rely on.

Supply Chain Reliability and Timely Deliveries

Global industries depend on timely delivery to maintain their production schedules and market competitiveness. CNC machining parts exporters, therefore, operate robust logistics systems and maintain reliable supply chains. They work closely with freight companies, manage customs documentation, and ensure compliance with import-export regulations. Many exporters maintain safety stock and have scalable production capabilities to accommodate rush orders and unforeseen demand spikes, making them reliable allies in just-in-time manufacturing.

Customization and Prototyping for Innovation

In an era of rapid innovation and shifting product cycles, the ability to customize components is more critical than ever. CNC machining parts exporters offer tailored solutions based on specific client designs. They work closely with R&D teams to develop prototypes, make iterative adjustments, and finalize parts that align with functional and performance goals. This flexibility supports industries in launching new products faster while reducing the cost and time associated with design changes.

Quality Assurance as a Core Competency

Quality is non-negotiable in industries like aerospace, healthcare, and electronics. CNC machining parts exporters employ rigorous quality assurance protocols at every stage of production. From raw material verification to in-process checks and final inspection, each step is meticulously documented and controlled. Advanced metrology tools such as coordinate measuring machines (CMM), laser scanners, and vision inspection systems ensure compliance with the most demanding tolerances and surface finish specifications. These consistent quality measures reinforce trust between exporters and global buyers.

Cost-Effectiveness and Competitive Pricing

While quality is paramount, global industries also seek cost-effective manufacturing solutions. CNC machining parts exporters, particularly those based in cost-competitive regions like China, India, and Southeast Asia, offer high-quality parts at significantly lower prices compared to Western markets. Their economies of scale, lean production methods, and efficient resource utilization allow them to deliver better value without compromising quality. This affordability empowers industries to control production costs and improve margins.

Expertise in Materials and Machining Techniques

Exporters often possess in-depth knowledge of a wide range of materials—aluminum, stainless steel, titanium, plastics, and specialty alloys. Their ability to machine these materials precisely while accounting for properties like thermal expansion, hardness, and wear resistance is critical for industries with specialized needs. Additionally, their proficiency in techniques such as turning, milling, drilling, tapping, and surface finishing ensures that components meet both functional and aesthetic requirements.

Long-Term Collaboration and Strategic Partnerships

CNC machining parts exporters are more than vendors—they are long-term collaborators who contribute to their clients’ strategic objectives. By offering technical consultation, flexible production models, and scalable capacity, they align closely with the goals of global businesses. Their commitment to reliability, transparency, and continuous improvement often leads to strategic partnerships that go beyond simple supplier relationships. For industries focused on sustainability and innovation, these partnerships offer long-term advantages.

Environmental Responsibility and Green Manufacturing Practices

As sustainability becomes a critical concern across sectors, many CNC machining exporters are embracing green manufacturing practices. These include the use of energy-efficient machines, recycling of metal scraps, reduction of waste, and environmentally friendly coolants and lubricants. Compliance with international environmental regulations like RoHS and REACH further strengthens their appeal to eco-conscious industries. This alignment with sustainability goals helps global buyers meet their own environmental commitments.

Risk Management and Business Continuity

Exporting CNC machined parts involves navigating geopolitical uncertainties, trade regulations, and logistics disruptions. Reliable exporters proactively address these risks by diversifying their sourcing, maintaining contingency plans, and fostering local partnerships in key markets. Their ability to adapt to changing circumstances while ensuring uninterrupted supply plays a crucial role in the resilience of global production networks.

Digital Integration and Industry 4.0 Adoption

Industry 4.0 technologies have been embraced by forward-thinking CNC machining parts exporters. These include IoT-enabled machines, predictive maintenance systems, and cloud-based production monitoring. Digital integration not only improves efficiency but also enhances transparency for buyers. Real-time tracking, automated reports, and data-driven insights enable better decision-making and foster collaborative manufacturing relationships.

Testimonials and Case Studies Reflecting Global Trust

The reliability of CNC machining parts exporters is best illustrated by the success stories of industries they serve. From multinational aerospace corporations sourcing precision components to medical device manufacturers relying on life-critical parts, exporters consistently prove their ability to deliver excellence. Case studies showcasing how exporters helped clients reduce lead times, improve product quality, or successfully launch new products reinforce their role as trusted global partners.

The Future Outlook for CNC Machining Export Industry

The CNC machining export industry is poised for continued growth driven by globalization, technological advancement, and increasing demand for precision components. As automation, AI, and hybrid manufacturing models (such as combining CNC with additive manufacturing) gain traction, exporters will evolve to offer even more sophisticated solutions. Emerging markets and increased digitalization will open new opportunities, and those who stay ahead of trends will become key players in shaping the future of global manufacturing.

Conclusion

Investing in CNC machining parts exporters are integral to the fabric of global manufacturing. Their ability to deliver precision, quality, and cost-efficiency across a wide range of industries makes them vital to the success of international supply chains. Through investment in technology, unwavering commitment to quality, and strong client partnerships, they have earned the trust of global industries. As manufacturing continues to evolve, the importance of CNC machining parts exporters will only deepen, reinforcing their position as essential drivers of industrial innovation and reliability.

Comentarios