What are the 5 Common Types of CNC Machines?

- hktenlita1

- May 14, 2024

- 4 min read

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry by automating complex processes, increasing precision, and boosting productivity. These machines are programmed with computer software to control their movements, ensuring high accuracy and repeatability. Various types of CNC machines are designed for specific tasks and applications. This blog will explore five common types of CNC machines: CNC Plasma Cutters, CNC Lathe and Turning Machines, CNC Laser Cutting Machines, CNC Electric Discharge Machines, and CNC Drilling Machines.

CNC Plasma Cutters

CNC Plasma Cutters are widely used in the manufacturing industry for cutting through electrically conductive materials, such as steel, aluminum, brass, and copper. The process involves generating a high-temperature plasma arc to melt the material while a jet of compressed gas blows away the molten metal, creating a precise cut. Plasma cutters are known for their speed and efficiency, making them ideal for cutting large sheets of metal quickly and accurately.

The key advantage of CNC Plasma Cutters is their ability to cut thick materials with high precision and minimal thermal distortion. They are commonly used in automotive repair shops, construction, and industrial manufacturing. Advanced CNC plasma systems can also handle intricate designs and complex shapes, often required in custom fabrication projects. Additionally, plasma cutting produces relatively clean edges, reducing the need for secondary finishing operations.

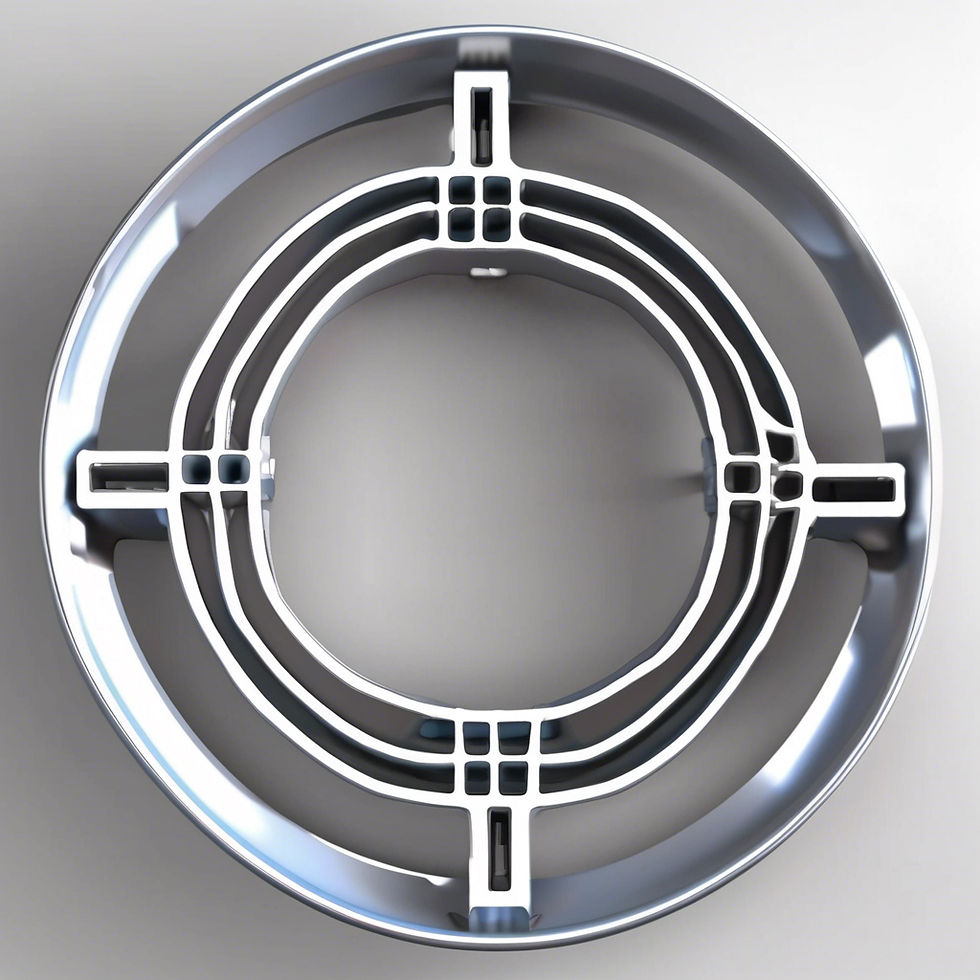

CNC Lathe and Turning Machines

CNC Lathes and Turning Machines are essential tools in the machining industry. They are primarily used for shaping cylindrical or conical parts. These machines rotate the workpiece around a fixed cutting tool, removing material to achieve the desired shape and size. CNC lathes are highly versatile and can perform various operations, including facing, threading, knurling, and drilling.

One of the significant benefits of CNC lathes is their ability to produce consistent and repeatable parts with high precision. They are widely used in aerospace, automotive, and medical device manufacturing industries, where precision and accuracy are critical. CNC turning machines can handle a range of materials, including metals, plastics, and composites, making them suitable for various applications. Additionally, modern CNC lathes are equipped with multiple axes and live tooling capabilities, allowing for complex machining operations in a single setup, thus increasing efficiency and reducing production time.

CNC Laser Cutting Machines

CNC Laser Cutting Machines utilize a focused laser beam to cut materials with extreme precision and high-quality finishes. The laser beam, generated by a CO2 or fiber laser source, melts, burns, or vaporizes the material, creating a clean and accurate cut. Laser cutting is particularly effective for intricate and detailed designs, as the laser can produce fine cuts and sharp corners.

These machines are commonly used in electronics, automotive, aerospace, and jewelry making, where precision and intricate details are paramount. CNC Laser Cutting Machines can cut various materials, including metals, plastics, wood, and textiles. One of the main advantages of laser cutting is its ability to produce minimal waste. The process is highly efficient and requires no physical contact with the material, reducing the risk of contamination and damage.

CNC Electric Discharge Machines

CNC Electric Discharge Machines (EDMs), also known as spark eroders or wire EDMs, are used to machine hard materials and create complex shapes that are difficult to achieve with traditional cutting tools. EDM generates a series of electrical discharges (sparks) between an electrode and the workpiece, eroding the material to form the desired shape. The process is typically carried out in a dielectric fluid, which helps to cool the workpiece and flush away the eroded particles.

EDMs are particularly useful for producing intricate details, fine finishes, and precise tolerances in hard materials such as tool steels, titanium, and tungsten carbide. They are widely used in the mold and die-making industry and in the production of aerospace components and medical devices. A significant advantage of EDMs is their ability to machine materials without inducing mechanical stresses or distortions, making them suitable for delicate and high-precision applications.

CNC Drilling Machines

CNC Drilling Machines are specialized tools designed to create precise and consistent holes in various materials. These machines use rotating drill bits to penetrate the workpiece, guided by programmed instructions to ensure accuracy and repeatability. CNC drilling is essential in many manufacturing processes, from creating holes for fasteners and rivets to producing intricate patterns in circuit boards.

The main advantage of CNC Drilling Machines is their ability to produce holes with consistent diameters and depths, reducing the need for manual intervention and inspection. These machines can handle a range of materials, including metals, plastics, and composites, and are commonly used in electronics, automotive, aerospace, and construction industries. Advanced CNC drilling systems can also perform other operations, such as tapping, countersinking, and reaming, making them versatile tools in a manufacturing environment.

Conclusion

CNC machines have transformed the manufacturing landscape by offering unparalleled precision, efficiency, and versatility. The five common types of CNC machines—CNC Plasma Cutters, CNC Lathe and Turning Machines, CNC Laser Cutting Machines, CNC Electric Discharge Machines, and CNC Drilling Machines—each serve specific purposes and applications, catering to the diverse needs of various industries. Understanding the capabilities and advantages of each type of CNC machine is crucial for selecting the right equipment from a reliable CNC machine supplier for your manufacturing processes, ultimately enhancing productivity and product quality. Whether you are cutting thick metal sheets, shaping cylindrical parts, creating intricate designs, machining hard materials, or drilling precise holes, there is a CNC machine designed to meet your specific requirements.

Commentaires