Why Buying Wholesale Sheet Metal Parts Can Lower Your Production Costs

- hktenlita1

- Apr 16

- 5 min read

In the world of modern manufacturing, cost-efficiency and streamlined processes are critical to staying competitive. One strategic move that many manufacturers and industrial businesses are leveraging is purchasing sheet metal parts in bulk. Wholesale sheet metal parts are not just about getting lower prices; they also contribute significantly to reducing overall production costs and enhancing operational efficiency.

This article explores how buying wholesale sheet metal parts can bring down production costs and why it's a smart strategy for businesses across various sectors.

Understanding Sheet Metal Parts in Manufacturing

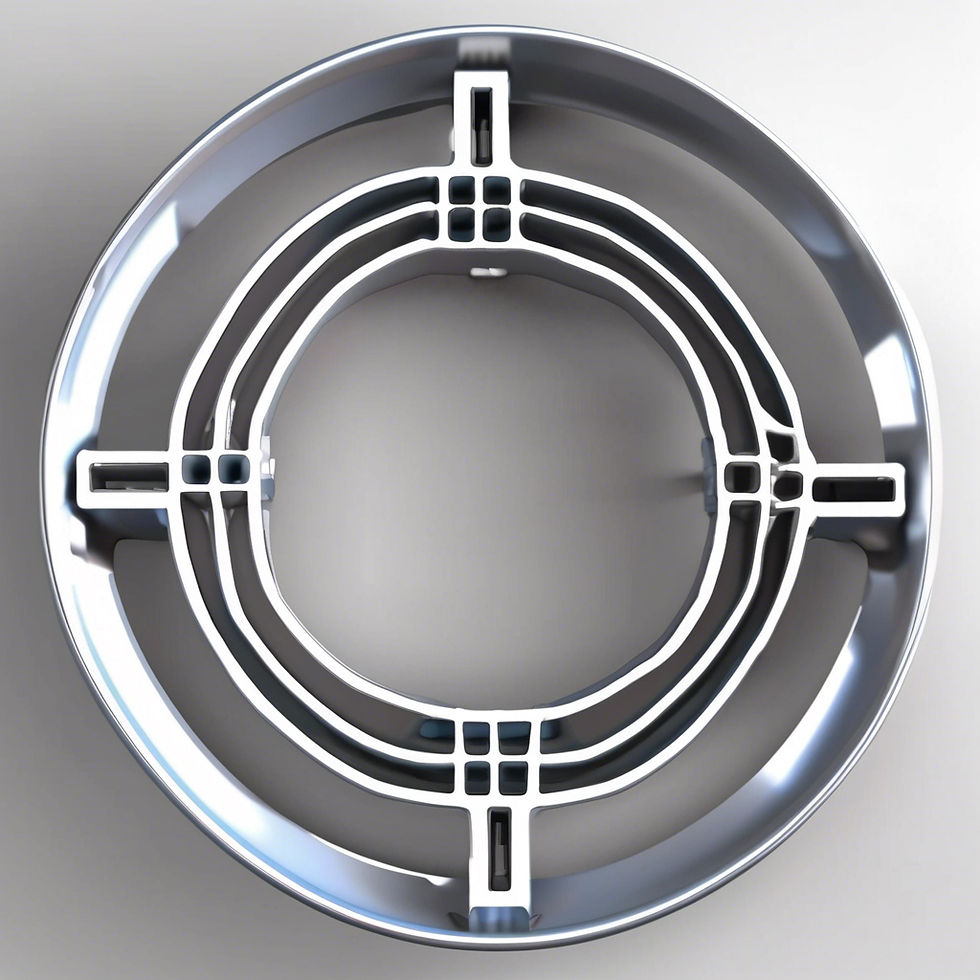

Sheet metal parts are widely used in industries such as automotive, aerospace, electronics, construction, and machinery. They serve as essential components in everything from enclosures and chassis to brackets and structural supports. These parts are usually produced using processes like stamping, bending, cutting, laser machining, and welding.

Due to their durability, lightweight properties, and design flexibility, sheet metal components are an integral part of both low- and high-volume production. However, the method of procurement can significantly influence both cost and efficiency.

Economies of Scale and Unit Cost Reduction

One of the most compelling reasons for purchasing wholesale sheet metal parts is the advantage of economies of scale. When you order parts in larger quantities, manufacturers can optimize their production setup. They spend less time on machine setup per part, reduce waste, and streamline labor requirements.

As the volume increases, the cost per unit drops. This is because fixed costs such as tooling, setup time, and administrative overhead are distributed over a larger number of parts. Lower per-unit costs mean more affordable products for you, which ultimately leads to reduced production expenses.

Reduced Procurement and Administrative Expenses

Every procurement transaction—whether large or small—requires time and administrative resources. From issuing purchase orders to processing payments and tracking deliveries, the cost of managing orders can accumulate quickly if purchases are made frequently in small batches.

Buying sheet metal parts wholesale reduces the number of purchase orders and delivery schedules you need to manage. This consolidation of administrative tasks helps free up staff time and reduce internal procurement costs, which adds up over time and directly benefits your bottom line.

Improved Supplier Relationships and Negotiation Leverage

Suppliers appreciate large and consistent orders. When you buy in bulk, you position yourself as a valuable customer, which opens the door for better terms, faster turnaround times, and prioritized service. This improved relationship can also lead to customized service offerings tailored to your production schedule.

Moreover, wholesale buyers often have greater negotiation power. You can discuss discounts, long-term pricing agreements, or added services like just-in-time deliveries or inventory stocking. All these factors contribute to overall cost savings.

Consistency in Quality and Specifications

Another often-overlooked benefit of wholesale purchasing is consistency in part quality. When parts are manufactured in a single batch or under the same production conditions, you're more likely to receive parts with uniform dimensions, finish, and structural integrity.

This consistency eliminates the costs associated with rework, product rejections, or adjustments on the assembly line. With fewer variations to account for, your production line can operate more smoothly and efficiently.

Lower Logistics and Shipping Costs

Ordering in bulk often means fewer shipments and, therefore, lower overall transportation expenses. Shipping one large order is usually more cost-effective than sending multiple smaller orders over time. Additionally, shipping in bulk allows for better packaging optimization and reduced handling costs.

Many suppliers offer discounted or even free shipping on large orders, especially for long-term customers. By consolidating shipments, you not only reduce the cost per unit shipped but also minimize the risk of delays that can disrupt production timelines.

Inventory Management and Production Scheduling Benefits

While it may seem counterintuitive, buying wholesale can actually support better inventory management. With a larger stock of critical sheet metal parts on hand, you reduce the risk of production delays due to supply chain disruptions.

Additionally, when your supply of components is reliable and predictable, you can plan production runs more effectively. This enhances throughput and minimizes costly downtime. Some businesses even use wholesale orders as part of a just-in-case inventory strategy to buffer against demand fluctuations.

Customization Opportunities at Lower Cost

Many wholesale sheet metal suppliers offer custom fabrication services at discounted rates for large orders. This is particularly valuable for manufacturers that need components designed to specific tolerances or configurations.

The cost of custom tooling, dies, or molds can be substantial when producing small batches. However, when these setup costs are spread over a large volume, the per-unit cost of customization drops significantly. This allows manufacturers to implement custom designs without blowing up the budget.

Reduced Risk of Price Fluctuations

Raw material prices are volatile, and so are manufacturing costs influenced by labor, energy, and transportation. Buying wholesale helps shield your business from short-term price hikes. You can lock in current prices for a large volume of parts, ensuring stability in your cost structure for future production runs.

Having this predictability is essential for maintaining competitive pricing, especially in industries where margins are thin. It also aids in more accurate budgeting and financial forecasting.

Support for Scalable Growth

When your business is growing, consistency and readiness become crucial. Wholesale purchasing ensures you have the parts you need to meet rising demand without delays or quality issues. It allows you to scale operations with confidence, knowing your supply chain is reliable and cost-effective.

Bulk buying also signals to potential clients or partners that your operation is capable of handling larger orders, which can lead to more opportunities and contracts. By securing your supply chain upfront, you make it easier to grow sustainably.

Environmental and Sustainability Considerations

Although not directly financial, there are cost-related environmental benefits to consider. Fewer shipments mean less packaging waste and reduced carbon emissions. Consolidating orders and transportation contributes to a more sustainable supply chain, which can improve your company’s image and fulfill environmental compliance requirements.

Moreover, manufacturers often optimize bulk production to reduce scrap material and energy consumption, which can lead to cost savings that are passed on to the buyer.

Real-World Example of Cost Reduction

Consider a mid-size electronics manufacturer that produces 5,000 enclosures per month. Initially, the company was ordering sheet metal components in small batches from local suppliers. Due to frequent reordering, high administrative workload, inconsistent quality, and premium pricing, their production costs were higher than expected.

After switching to a wholesale supplier overseas and ordering 50,000 units at a time, they saw a 30% reduction in per-unit costs. Not only did they benefit from better pricing, but the supplier also offered free shipping and priority scheduling. This change alone led to a six-figure annual savings and improved their production timelines.

Choosing the Right Wholesale Sheet Metal Supplier

To truly benefit from wholesale purchasing, selecting the right supplier is crucial. Look for a manufacturer with a track record of quality, the capacity for large orders, and flexibility in customization. Certifications, customer reviews, and sample evaluations can help you make an informed decision.

Establish clear communication channels and be upfront about your production requirements and expectations. A supplier who understands your business goals will be better positioned to support you in reducing production costs over the long term.

Final Thoughts

Lowering production costs isn't just about cutting corners; it's about optimizing processes and making smart, strategic decisions. Buying wholesale sheet metal parts is one such decision that can lead to substantial savings, smoother operations, and more predictable supply chains.

Whether you're a small manufacturer scaling up or an enterprise optimizing your procurement strategy, wholesale purchasing offers a host of benefits that go beyond price. It's a long-term approach to cost management that empowers businesses to stay competitive in a dynamic global market.

Comments