Why Global Buyers Choose China Sheet Metal Parts Manufacturers

- hktenlita1

- Apr 16

- 6 min read

In the evolving landscape of global manufacturing, sourcing reliable and cost-effective components has become essential for businesses aiming to stay competitive. Sheet metal parts, used extensively across industries like automotive, electronics, construction, and aerospace, are critical elements in product development. For global buyers seeking high-quality yet affordable sheet metal solutions, China has emerged as a leading hub. But what drives this preference for Chinese manufacturers? This article explores the key reasons why global buyers consistently choose China sheet metal parts manufacturers for their sourcing needs.

Competitive Pricing Without Compromising Quality

One of the primary reasons global buyers gravitate toward Chinese sheet metal manufacturers is their ability to deliver high-quality products at competitive prices. China's mature supply chain, abundant raw materials, and extensive manufacturing infrastructure enable producers to reduce production costs. These savings are passed on to buyers, making Chinese products economically attractive.

Furthermore, many manufacturers in China use advanced machinery and efficient production techniques, ensuring that lower costs do not come at the expense of quality. This balance between affordability and reliability is a compelling proposition for international businesses aiming to optimize their profit margins.

Advanced Manufacturing Capabilities and Technology Adoption

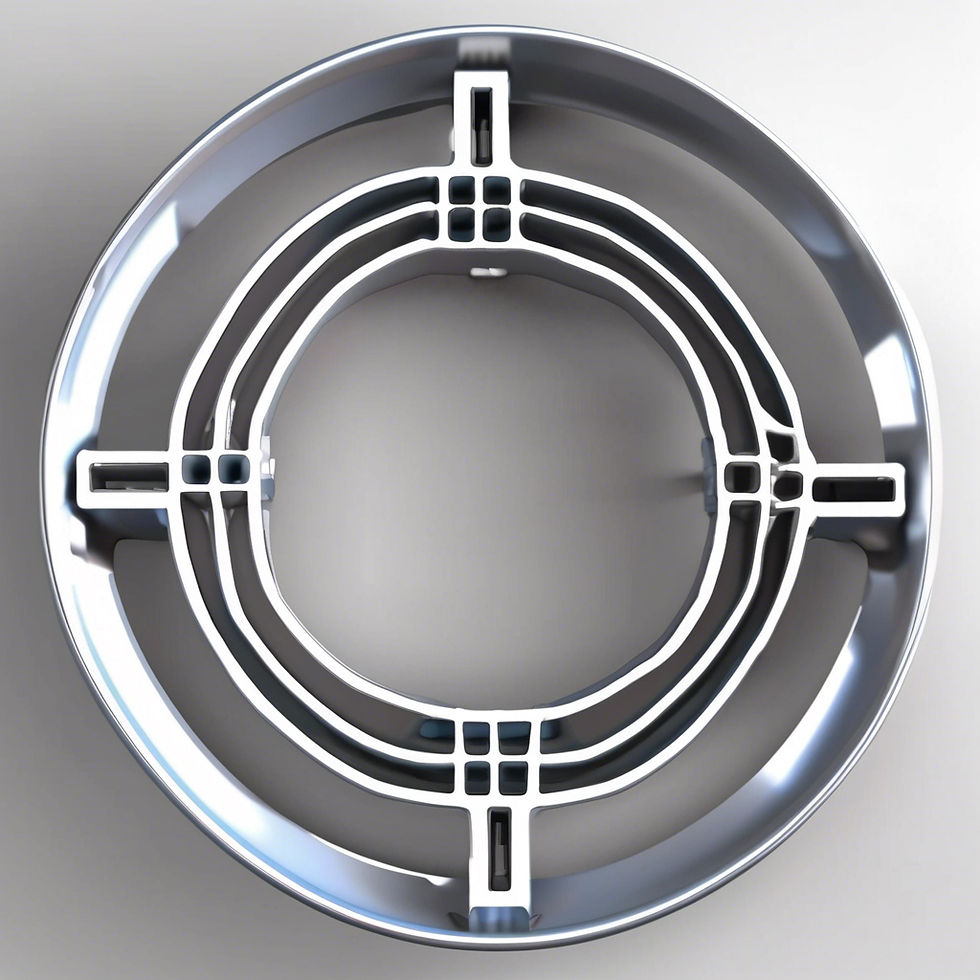

Chinese manufacturers have rapidly adopted cutting-edge technology in sheet metal fabrication. From laser cutting and CNC punching to robotic welding and automated bending machines, modern Chinese factories are equipped with the latest machinery.

This investment in technology has allowed manufacturers to meet complex design requirements and maintain tight tolerances, matching or exceeding the capabilities of manufacturers in more developed economies. As a result, global buyers can confidently outsource even high-precision and custom sheet metal components to Chinese suppliers.

High Production Capacity for Large Volume Orders

China’s vast industrial base allows its manufacturers to handle large-volume orders with efficiency and consistency. For global companies scaling up production or launching large projects, the capacity of Chinese manufacturers offers a crucial advantage.\

Large factories in China operate around the clock, often with multiple production lines dedicated to sheet metal fabrication. This scalability ensures that buyers receive their orders on time, even for substantial quantities. The ability to fulfill large orders quickly is essential for industries with tight deadlines and high demand variability.

Skilled Workforce and Engineering Expertise

Another critical factor behind China’s dominance in sheet metal manufacturing is its skilled workforce. The country has cultivated a large pool of technicians, engineers, and machinists with extensive experience in metal fabrication.

Many Chinese manufacturers also employ dedicated R&D teams and product engineers who assist global buyers with product design, prototyping, and process optimization. This engineering support helps buyers refine their designs, reduce material waste, and achieve better functional performance, contributing to long-term cost savings and product innovation.

Strong Supplier Ecosystem and Integrated Supply Chains

China’s manufacturing strength is not limited to individual factories but extends to a comprehensive ecosystem of suppliers, subcontractors, and logistics providers. This ecosystem facilitates the seamless integration of services such as stamping, forming, surface finishing, and assembly.

Global buyers benefit from this integration as they can source complete assemblies or finished components from a single supplier. It reduces the need to manage multiple vendors and streamlines procurement processes. The time and cost savings achieved through this integrated approach are significant, especially for companies managing international supply chains.

Customization and Flexibility in Design Requirements

Modern industries often require highly customized sheet metal components tailored to specific applications. Chinese manufacturers are known for their flexibility in accommodating custom designs, materials, and finishes. Whether it’s a prototype for a new product or a redesigned component for improved performance, Chinese suppliers are quick to adapt.

Thanks to in-house tooling capabilities and efficient production planning, many Chinese factories can switch between different product types or introduce design changes with minimal disruption. This adaptability is invaluable for buyers working in dynamic markets where product iterations are frequent.

Timely Delivery and Efficient Logistics Support

While distance might seem like a challenge when sourcing from China, the country’s well-developed logistics infrastructure ensures timely deliveries. With access to major seaports, air freight options, and global courier services, Chinese manufacturers can ship products to virtually any corner of the world efficiently.

In addition, many suppliers offer consolidated shipping, real-time tracking, and customs documentation assistance. These services minimize delays and simplify the import process for international buyers. Timely delivery translates to uninterrupted production schedules and improved business continuity.

Compliance with International Standards and Certifications

A common concern among global buyers is whether overseas manufacturers adhere to international quality and safety standards. Leading Chinese sheet metal parts manufacturers recognize this requirement and often hold certifications such as ISO 9001, ISO 14001, RoHS, and CE.

These certifications ensure that the products meet stringent quality control guidelines and environmental regulations. In sectors like automotive, aerospace, and medical devices, where compliance is non-negotiable, Chinese manufacturers' commitment to international standards provides assurance to buyers around the world.

Cost-Effective Prototyping and Low Volume Production

Before mass production begins, many companies need prototypes or small batches for testing and validation. Chinese manufacturers offer cost-effective prototyping services with fast turnaround times. By leveraging local resources and efficient fabrication processes, they help global buyers accelerate their product development cycles.

For startups and small businesses, this access to affordable prototyping in China reduces the initial investment and lowers the barrier to market entry. The ability to produce low volumes at competitive prices is a unique advantage that supports innovation and flexibility.

Positive Track Record and Client Testimonials

China’s reputation as a reliable manufacturing partner is supported by numerous success stories and client testimonials from around the world. Many global brands and original equipment manufacturers (OEMs) have established long-term relationships with Chinese sheet metal parts manufacturers due to their consistent performance and customer-centric approach.

From meeting strict delivery timelines to resolving technical challenges promptly, Chinese manufacturers have demonstrated their capability to handle the demands of international clients. This track record of reliability continues to strengthen their appeal among global buyers.

Language Proficiency and International Communication

Effective communication is crucial when collaborating across borders. Over the years, Chinese manufacturers have significantly improved their language proficiency and international communication skills. Many employ English-speaking sales and engineering teams who can discuss technical specifications, respond to queries, and provide updates with clarity and professionalism.

Improved communication reduces the risk of misunderstandings and errors, enabling smoother collaboration. Global buyers appreciate this level of engagement and find it easier to build trust with their Chinese counterparts.

Government Support and Policy Initiatives

China’s central and local governments actively support the manufacturing sector through favorable policies, infrastructure development, and export incentives. These initiatives contribute to the overall efficiency and global competitiveness of Chinese manufacturers.

From tax benefits to subsidies for technology upgrades, these policies enhance the capabilities of sheet metal manufacturers and allow them to offer better value to international buyers. Stable governance and policy continuity also provide a reliable business environment for long-term partnerships.

Emphasis on Quality Control and Continuous Improvement

Modern Chinese manufacturing facilities are increasingly focused on quality assurance and continuous improvement. Quality control departments use advanced inspection tools such as coordinate measuring machines (CMMs), laser scanners, and non-destructive testing equipment to ensure every product meets the required standards.

Incorporating Six Sigma methodologies, lean manufacturing practices, and statistical process control has become common in many factories. These quality management practices align with global expectations and reduce defects, rework, and warranty claims, ultimately benefiting the buyer.

Access to Diverse Material Options and Surface Finishes

China’s rich network of material suppliers ensures easy access to a wide range of metals such as aluminum, stainless steel, carbon steel, and copper. This availability allows buyers to select the most suitable material based on performance, budget, and aesthetic considerations.

Additionally, Chinese manufacturers offer diverse surface treatments such as powder coating, anodizing, electroplating, sandblasting, and painting. These finishing services add functional and visual value to sheet metal parts, making them suitable for end-use applications straight from the factory.

Strategic Location for Global Trade

Located at the heart of Asia, China enjoys a strategic geographical position for global trade. It offers fast and cost-effective shipping routes to North America, Europe, Southeast Asia, and the Middle East. This geographical advantage, combined with a robust port and logistics infrastructure, supports timely deliveries and competitive freight rates.

For multinational companies operating across multiple regions, sourcing from China ensures convenient access to both raw materials and end markets, making the supply chain more agile and responsive.

Building Long-Term Strategic Partnerships

For many global buyers, the relationship with a sheet metal parts manufacturer goes beyond a transactional purchase. It’s about forming a strategic partnership that supports growth, innovation, and mutual success. Chinese manufacturers understand this dynamic and are committed to building long-term business relationships.

They invest in understanding client needs, sharing market insights, and supporting product development initiatives. This collaborative approach creates a sense of partnership rather than a vendor-client divide, paving the way for sustainable business success.

Final Thoughts

China's dominance in sheet metal part manufacturing is not accidental. It is the result of decades of investment, skill development, and a relentless focus on delivering value. From cost advantages and advanced technology to customization capabilities and robust logistics, Chinese manufacturers offer a comprehensive solution for global buyers.

As industries become more competitive and supply chains more complex, partnering with a reliable and capable manufacturer becomes critical. For buyers seeking efficiency, scalability, and consistent quality, China remains the top destination for sourcing sheet metal parts.

Choosing a Chinese manufacturer is not just about cost savings; it's about tapping into a vast ecosystem that supports innovation, speed, and global competitiveness. For companies aiming to future-proof their operations, working with China sheet metal parts manufacturers continues to be a smart and strategic choice.

Comments